IECE Transactions on Education and Learning Technologies

ISSN: request pending (Online)

Email: [email protected]

In the context of the current era of profound industrial transformation, achieving new industrialization is a critical task for the comprehensive advancement of national strength. Strengthening new engineering education has become a pivotal focus of higher education reform. New engineering education aims to cultivate innovative engineering and technical talents who are well-aligned with the needs of the new era. The construction of new engineering education involves deepening innovations in several key areas, including organizational models, talent cultivation mechanisms, content methodologies, and the integration of theory and practice [1]. In this context, universities and colleges must actively contribute to the advancement of new industrialization and the development of new productivity. There is an urgent need to promote the iterative upgrading of new engineering education and establish a progressive practice teaching system, encompassing "basic practice, professional practice, comprehensive practice, and innovative practice" [2]. To better serve national new engineering education initiatives, the Ministry of Education has established the National Innovation Center for New Engineering Education, launching two batches of 1,457 new engineering research and practice projects. The concept of new engineering education has been widely disseminated across the higher education sector and has received significant recognition within the industrial community [3]. In this new phase of development, new engineering education is tasked with fostering new high-quality productivity, promoting new industrialization, advancing the digital transformation of education, reshaping the structure of higher education, and contributing to the construction of a strong educational system to support the creation of a new development pattern.

As a vital component of the engineering field, the automation profession possesses both traditional and innovative characteristics. 1) Automation is a traditional engineering discipline, fundamental to China's industrialization process. Since the Industrial Revolution, automation technology has played a crucial role in key sectors such as manufacturing, transportation, and aerospace, contributing to the development of these industries. The rich engineering experience accumulated over time has provided a solid foundation for the growth of the field [4]. 2) With the progression of technological advancements, the automation discipline has continuously integrated new technologies and ideas, exhibiting remarkable innovative potential. It is now facing new challenges and expanding its scope in the contemporary era. In the context of the new engineering education reforms, the reform of in-class experiments in automation is particularly significant, as it directly impacts the quality of engineering education and the enhancement of students' practical abilities [5]. As emerging technologies such as artificial intelligence and the Internet of Things advance, automation systems are becoming increasingly complex, intelligent, and integrated. This evolution necessitates professionals to not only master traditional control theories and electrical technologies but also acquire interdisciplinary skills such as data analysis, machine learning, and software programming. These competencies are essential for achieving precise control, intelligent decision-making, and optimized management of automation systems. Simultaneously, the application areas of automation are expanding, extending from traditional industrial automation to emerging sectors such as intelligent healthcare, smart agriculture, and workflow automation, thus fueling the intelligent development of society [6]. In the process of promoting industrial upgrading and economic transformation, the automation profession plays a crucial role in driving technological innovation and supporting the implementation of strategies like intelligent manufacturing and smart cities. Consequently, there is an urgent need to continuously innovate the curriculum system, strengthen practical teaching, and cultivate innovative engineering and technical talents to meet the demands of the evolving era.

The "Freshman Engineering Experience" program, offered by Beijing Technology and Business University (BTBU), serves as the inaugural professional course for students majoring in automation. This course is a typical introductory offering within emerging engineering disciplines. The curriculum integrates both theoretical knowledge pertinent to the major and practical experiences, such as guiding students in constructing simple robots, organizing professional knowledge debates, and facilitating visits to off-campus practical training sites. The primary objective of this course is to provide students with a clear understanding of the program's educational goals. Through this course, students are expected to gain insight into the aims of professional training, familiarize themselves with the theoretical advancements and methodologies of the field, and enhance key skills such as observation, communication, and hands-on abilities. The course aims to equip students with the necessary skills to apply automation knowledge in analyzing and solving problems, thereby fostering innovation and practical application in new engineering domains. Ultimately, this experience lays a solid foundation for their continued studies in subsequent courses.

Recent studies have systematically advanced engineering education through innovative pedagogical approaches. In 2023, Martin et al. [7] examined the historical evolution of engineering education, highlighting the shifting responsibilities of technological universities, though their broad historical scope may lack specific implementation guidelines. The following year witnessed significant developments, with Pacher et al. [8] in 2024 proposing Engineering Education 5.0 for industrial engineering, emphasizing competence-based learning while facing challenges in standardized assessment methods. Also in 2024, Tembrevilla et al. [9] demonstrated the efficacy of experiential learning in enhancing practical skills, despite its resource-intensive nature requiring substantial faculty training. Concurrently, Muzata et al. [10] in 2024 explored VR-based immersive learning environments, offering transformative potential through realistic simulations, yet constrained by high implementation costs and technological barriers. These studies collectively represent the field's progression toward more applied, competency-focused, and technologically-enhanced educational paradigms, while revealing persistent challenges in scalability and practical implementation across different institutional contexts.

We identify two key challenges that must be addressed in the context of new engineering education within the "Freshman Engineering Experience" program:

First, a critical challenge is to break the constraints of the traditional curriculum structure within the knowledge system of new engineering disciplines and to establish a new curriculum and talent development system that promotes multidisciplinary cross-fertilization [11, 12]. This approach would enable students to gain a deep understanding of the interdisciplinary nature of new engineering fields and engage in comprehensive, cross-disciplinary experimental projects. For instance, the "Intelligent Control and Robotics" module integrates knowledge from various disciplines, including control theory, computer programming, and mechanical design, providing students with a systematic and holistic learning experience. Similarly, the "Intelligent Control and Robot Technology" module blends multidisciplinary knowledge to offer a comprehensive and structured curriculum for students.

Secondly, a key challenge is addressing the disconnect between theoretical knowledge and practical application in the "Freshman Engineering Experience" course. This involves integrating both theoretical and practical teaching content, thereby overcoming the traditional separation of theory and practice in engineering education. Additionally, it is essential to closely combine cultural and ethical considerations with practical applications, guiding students to recognize the importance of aligning technological innovation with ethical principles in engineering practice. This can be achieved through the analysis of typical case studies, the simulation of real-world engineering scenarios, and the use of virtual simulation software [13]. Such approaches will enable students to better understand and apply theoretical knowledge in practical contexts, enhancing their ability to bridge the gap between theory and practice.

In the reform of cultural education for automation in new engineering majors, we fully recognize that any reform must be theoretically grounded, avoiding the approach of "blind men feeling the elephant." Therefore, we rely on foundational pedagogical theories, such as the formulation of teaching content, the role and principles of assessment, and the integration of ideology and cultural education.

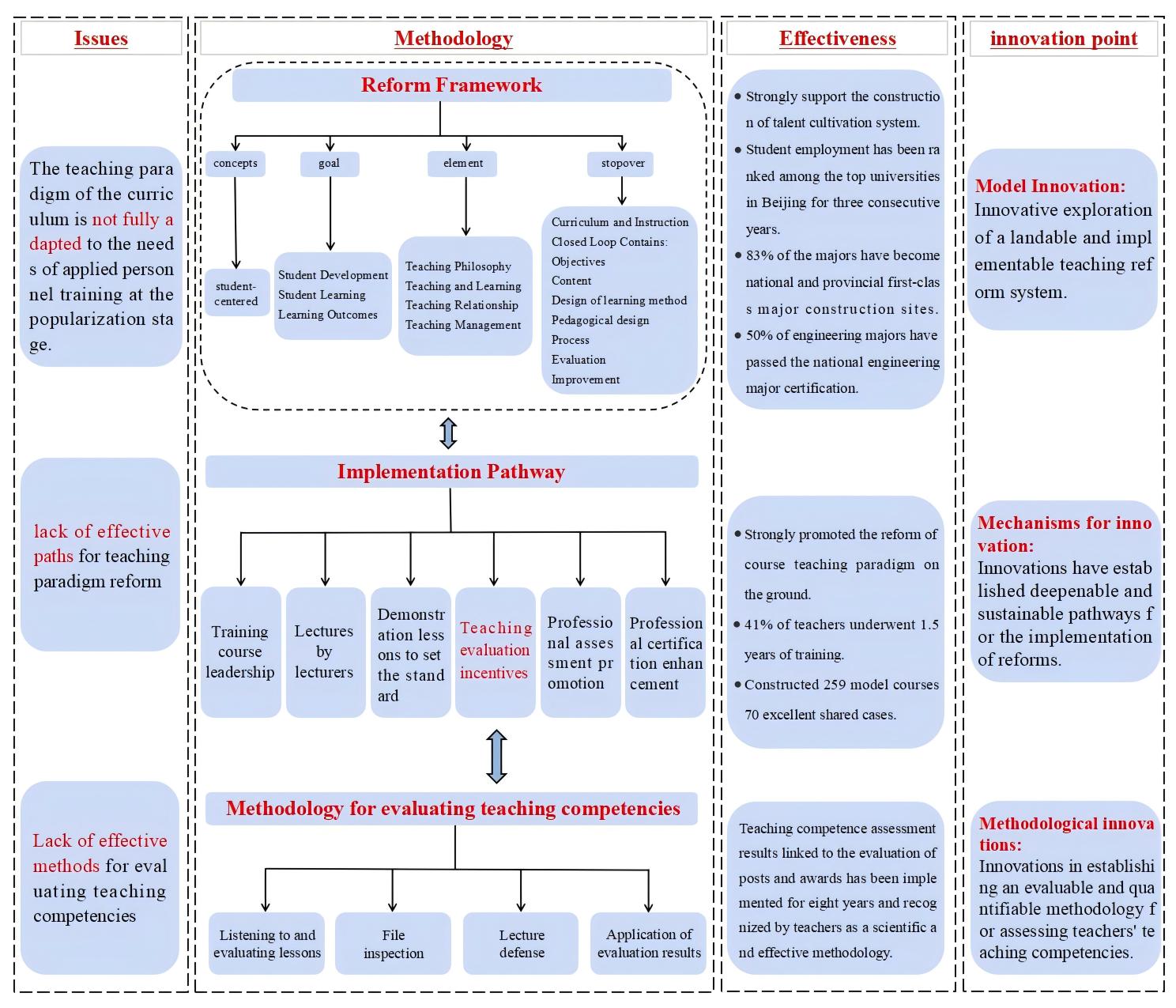

These are combined with the professional knowledge system of automation and the scientific, objective laws governing the process of cultural education. By centering our research on the cultural education process within the context of new engineering disciplines, we conduct a comprehensive analysis of the "Freshman Engineering Experience" as part of this process. Through this, we explore a new educational model based on the core values of new engineering majors, culminating in a framework for reforming cultural education within automation and evaluating its effectiveness, as depicted in Figure 1.

This study proposes a comprehensive framework for curriculum teaching reform aimed at enhancing applied talent cultivation. We identify critical gaps in current pedagogical paradigms and develop a systematic approach incorporating conceptual foundations, implementation pathways, and an innovative teaching competency evaluation system. The framework emphasizes student-centered learning optimization through leadership cultivation, faculty training, and multidimensional assessment techniques. Our contribution lies in establishing a practical, sustainable reform model that bridges theoretical frameworks with actionable solutions for higher education institutions, addressing both immediate implementation needs and long-term quality improvement in applied education.

In this process, we focus on reforming the teaching paradigm [14], innovating teaching concepts, enhancing professional development, and refining evaluation systems [15] to address issues such as insufficient innovation in teaching methods. The reform has led to significant improvements, including increased student employment rates, progress in professional development, and achievements in curriculum design. Concurrently, we explore teaching paradigms that can be effectively implemented and scaled, develop innovative methods for evaluating teaching capabilities, and motivate educators to improve their teaching skills, thereby providing robust support for talent cultivation.

With the goal of cultivating innovative practical abilities to meet the demands of "future intelligent manufacturing technologies," we establish a student-centered teaching approach aimed at enhancing students' innovative practice capabilities and comprehensive skills. This approach continues to deepen the reform of the innovative practice system within the curriculum. For example, in the "Freshman Engineering Experience" course, interdisciplinary cross-fertilization is strengthened by integrating disciplines such as the Internet of Things (IoT), artificial intelligence, and others [16, 17]. Additionally, the course content incorporates the development of real-world system projects, adapting to the practical needs of the course. Tasks such as using small development boards for actual project development are introduced, where students are encouraged to select topics and design multiple systems.

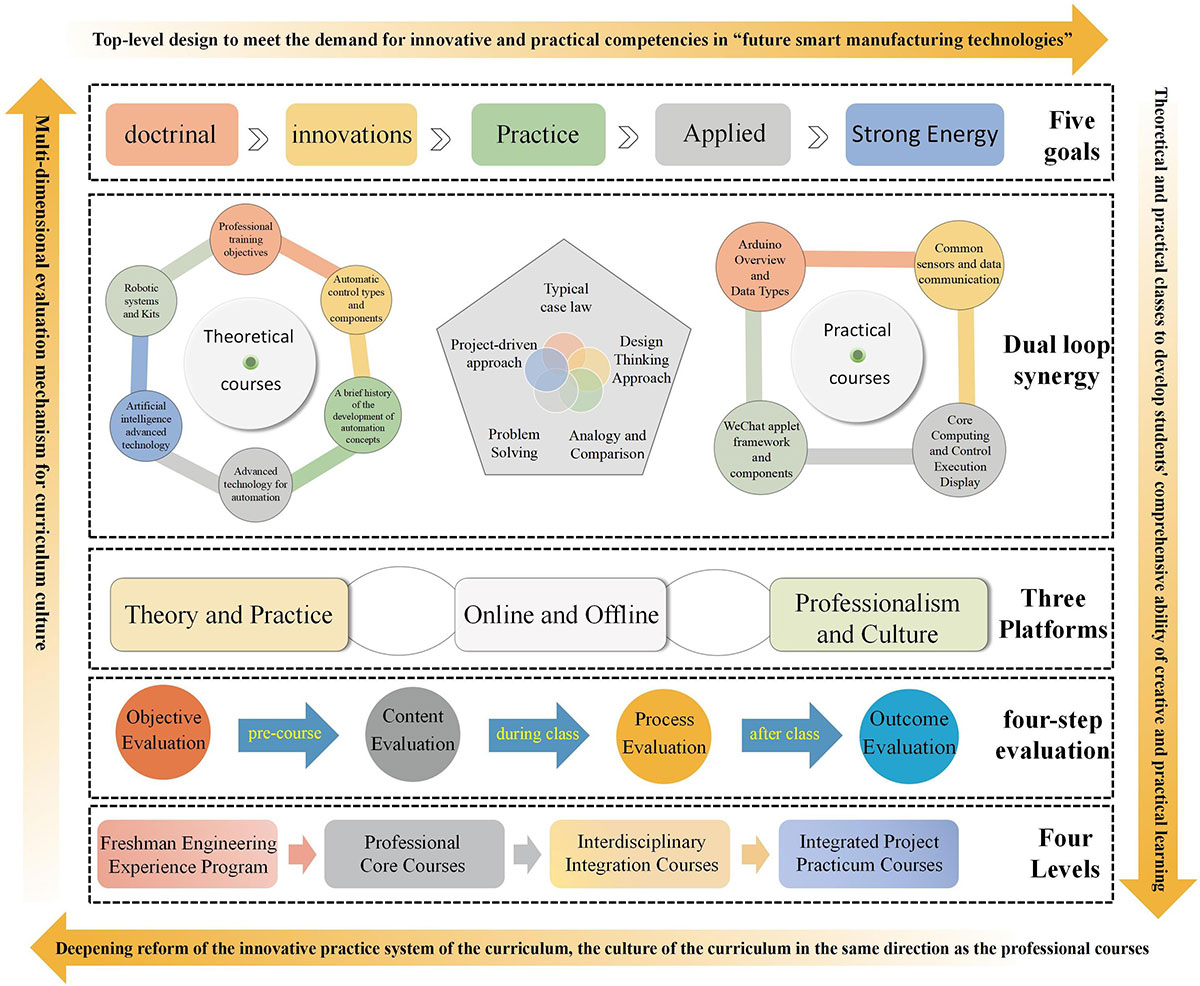

The "Freshman Engineering Experience" course is divided into theoretical and practical sessions, with theoretical knowledge and practical skills reinforcing each other. This structure facilitates a step-by-step learning process, progressing from foundational to advanced levels. The course system, as depicted in Figure 2, aims to enhance students' professionalism and comprehensive abilities across various domains, with the following objectives:

This study proposes a systematic framework for cultivating intelligent manufacturing innovation talents, integrating five core educational objectives (theoretical mastery, innovative thinking, practical skills, application competence, and professional capability) with three supporting platforms (theory-practice integration, blended learning, and disciplinary-cultural convergence). The framework features a dual-loop synergy mechanism that bridges theoretical and practical instruction, complemented by a four-phase evaluation system (objective-based, pre-course, formative, and summative assessments) for comprehensive quality monitoring. Implementation is achieved through a progressive four-level curriculum system, ranging from introductory engineering experiences to interdisciplinary capstone projects. This integrated approach demonstrates rigorous alignment among educational goals, support infrastructures, quality assurance mechanisms, and instructional delivery, offering a replicable model for advanced manufacturing education that effectively addresses the theory-practice divide while fostering interdisciplinary innovation capabilities.

First, based on comprehensive theoretical foundations, a teaching model of "internal and external synthesis" is constructed. Within the discipline, this model integrates theoretical teaching, experimental operation, and practical application through multi-dimensional teaching resources. Leveraging the discipline's comprehensive practice courses, the curriculum knowledge and basic skills are systematically summarized and integrated, enabling a personalized educational trajectory [18]. This approach aims to establish a more complete system of disciplinary knowledge and skills. At the interdisciplinary level, the "Freshman Engineering Experience" course facilitates the deep integration of multidisciplinary knowledge and skills, promoting a shift in educational philosophy from pure "knowledge acquisition" to "competence development." This transformation is achieved through the following instructional contents, aligning with the educational concept of fostering competence rather than solely focusing on knowledge mastery [19].

Professional Training Objectives and Talent Quality Requirements: This section outlines the professional training objectives, curriculum structure, and intrinsic relationships within the automation discipline. It guides students in conceptualizing their four-year study plan as the foundation of their academic journey, establishing a solid professional understanding and clarifying their learning direction and goals.

Core Theory of Automation: The core theory section addresses the types and composition of automatic control systems, as well as the concepts and historical development of automation. It describes the components of automatic control systems and the definitions, characteristics, and developmental history of control and automation. After students gain a preliminary understanding of the field, the core of automation—control systems—is examined in detail to help students grasp the underlying mechanisms of automation technology.

Theory of Advanced Technology: This section introduces advanced automation technologies, including artificial intelligence, robotic systems, and kits, divided into three parts. It covers the development history, principles, trends, and characteristics of these technologies, encompassing big data, cloud platforms, and other emerging fields. The development stages of artificial intelligence, along with its definitions, classifications, key technologies, and industrial applications, are explained. Practical case studies are used to demonstrate the evolution of these fields. After students acquire a foundational understanding of automation, current advanced technologies are introduced to keep them up-to-date, emphasizing the deep integration of automation and artificial intelligence. This section also explores cutting-edge developments in automation technology. Furthermore, the compilation environment for robotic systems, the principles of processing chips, sensor applications, communication modules, and WeChat applet development are introduced. Serving as a summary of theoretical classes and a bridge to practical applications, this section enables students to comprehensively apply their knowledge of automation and artificial intelligence. By studying robotic systems and kits, students are equipped to design and implement complex automation and intelligent systems, such as constructing intelligent robotic systems using sensors and control equipment, and controlling robots via WeChat applets.

Secondly, an "iterative and progressive" path for capability cultivation is established, guided by problem-solving and practical application. The development of capabilities should adhere to the principle of gradual progression, with subsequent practical teaching sessions designed based on the outcomes of preceding ones. The teaching content of the following four practical courses utilizes the overall engineering system as the framework, with a series of interconnected design tasks serving as the main teaching line. This approach transitions from simple to complex task, from discrete operations of individual modules to the joint collaboration of multiple modules, and from basic unit-level skills training to the comprehensive application at the system level. These tasks are divided into task-based, subject-based, and problem-based projects [20], transforming the stage-by-stage development of competence into a hierarchical, systematic, and coherent process.

Overview of Arduino and Data Types: This section aims to familiarize students with the characteristics, structure, and programming principles of the Arduino microcontroller. Students will master the use of the Microduino kit and Arduino IDE. As an introductory component of the practical course, this phase focuses on basic microcontroller program design, enabling students to acquire essential hardware operation and programming skills.

Commonly Used Sensors and Data Communication: This section introduces students to the working principles and application methods of various sensors, as well as the principles and usage of diverse data communication technologies. After acquiring basic programming skills, students will learn to connect the microcontroller with external devices, facilitating data acquisition and transmission.

Core Arithmetic and Control Execution Display: Students will gain an understanding of the principles and functions of processing chips, mastering the working principles and operation methods of command execution equipment. This phase further enhances students' practical abilities by teaching core computing and control execution display technologies, thereby enabling them to design and implement automation systems with specific functions.

WeChat Mini Program Framework and Components: In this section, students will learn how to utilize the framework, components, and APIs of WeChat Mini Programs to design applications with complex functionalities. As an extension of the practical course, the introduction to WeChat applet development allows students to integrate automation technology with mobile internet applications, fostering innovative thinking and enhancing comprehensive application skills.

Upon completion of the theoretical study and practical exercises in each chapter, students will engage in a comprehensive, systematic practice. At this stage, they will design and implement a complex automation and intelligent system project, integrating all previously learned knowledge and skills. For instance, students may design a smart home system that collects environmental data (such as temperature, humidity, and light) through Arduino microcontrollers and sensors, processes data and makes intelligent decisions using core computing equipment, and realizes a user interface display and remote-control function via a WeChat applet. This comprehensive system practice not only serves as an application of the knowledge acquired in earlier chapters but also acts as a comprehensive assessment of students' overall abilities and innovation.

In the teaching process, activities such as "literature search and report," "academic knowledge speech contest," and "innovation contest defense" are incorporated. These activities provide students with course-related topics, which they then prepare in groups and share their learning outcomes with the class. This approach effectively cultivates students' abilities in literature search, reading, teamwork, and speech expression. The "Creator Innovation Competition" and similar activities promote talent development within the competition-course integration model by leveraging competitions to drive teaching and learning [21]. This strategy enhances students' initiative in learning, solidifies their knowledge base, and broadens their understanding of the subject matter.

| Category |

|

|

|

||||||||||

|

|

Development history of automation |

|

||||||||||

|

Development history of automation | ||||||||||||

|

Compasses in China's Ancient Warfare |

|

|

||||||||||

| Fighter and Missile Technology | Automation Technology | ||||||||||||

|

|

|

|

||||||||||

| Innovation Examples - Sensors in Spacecraft |

|

||||||||||||

|

|

||||||||||||

| Advanced People | Qian Xuesen | Development of automatic control |

|

The adoption of a comprehensive assessment methodology has fundamentally transformed the evaluation paradigm, significantly diminishing the weighting of terminal examinations within the overall course assessment framework. This pedagogical shift has been characterized by an increased emphasis on formative assessment strategies, prioritizing the progressive accumulation of knowledge and competencies throughout the instructional period. The conventional grading system has been restructured to incorporate multiple evaluative components, including but not limited to attendance records, homework assignments, literature review and report composition, academic presentation competitions, and experimental outcomes. The assessment ratio has been established at 4:6 for continuous evaluation versus final assessment, with specific weightings allocated as follows: attendance (5%), homework completion (10%), experimental performance (10%), and report quality (25%).

The terminal evaluation comprises two principal components: the "Creator Innovation Competition Defense" and the comprehensive final examination. The defense mechanism is subjected to rigorous scrutiny by a panel of experts comprising both industry professionals and academic supervisors, who conduct a multidimensional evaluation of team presentations, individual contributions, and innovative entrepreneurial competencies. This comprehensive assessment framework, through its structured distribution and multifaceted approach, effectively incentivizes students to engage in autonomous learning, develop effective learning methodologies, identify novel research problems, acquire new knowledge domains, and enhance their theoretical understanding, practical skills, and cross-cultural competencies, thereby fostering a more holistic educational experience.

Based on the staged and systematic nature of undergraduate education, as well as the unique characteristics of automation majors, this study focuses on the undergraduate students enrolled in the "Freshman Engineering Experience" lectures as the research subject. Data was collected through a questionnaire survey, followed by in-depth analysis. The study identifies key aspects of professional cultural education, aiming to highlight the factors of cultural education that should be considered in fostering engineering students' engagement in activities and preparing them to solve problems [22]. The primary goal is to inspire the integration of cultural education factors in the development of engineering students and their problem-solving capabilities.

Table 1 presents some of the cultural and educational elements integrated into the "Freshman Engineering Experience Course."

This study conducts a comprehensive analysis of the constituent elements of professional culture across multiple educational contexts, encompassing undergraduate admissions processes, academic curricula, extracurricular student organizations, and research-oriented competitive platforms.

The investigation particularly focuses on the pivotal role of traditional cultural paradigms in shaping students' epistemological frameworks, academic integrity, and the foundational development of professional ethical standards throughout their academic trajectory from matriculation to graduation.

At the founding of the People's Republic of China, Qian Xuesen and a group of patriotic scholars returned to China and contributed to the nation's technological development, positioning China at the forefront of global technology. This patriotic spirit remains an exemplary model for students.

Today, intelligent manufacturing technology, which represents the Fourth Industrial Revolution, underscores the continued leadership of automation technology in shaping the global economic and technological landscape.

The Freshman Engineering Experience course plays a crucial role in automation education by providing first-year students with an introduction to the profession, thereby establishing a foundation for subsequent learning. The automation program has achieved significant teaching outcomes through innovative teaching activities and practical projects. These outcomes are analyzed from three key dimensions: students' work display, a comprehensive description of the work, and an analysis of students' performance.

1) Electronics and Embedded System Category:

The "Lighting Matrix" created through the Gluttony Snake mini-game demonstrates a breakthrough in traditional design. This homemade gaming device showcases the creative application of electronic components and software programming.

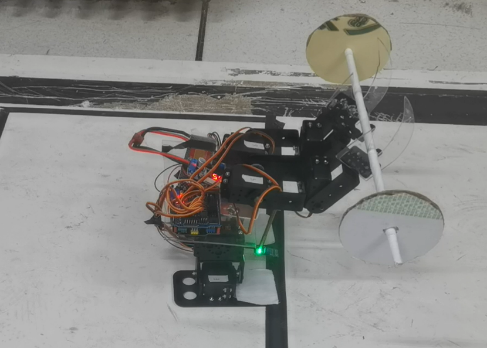

2) Mechanical Design and Manufacturing Category:

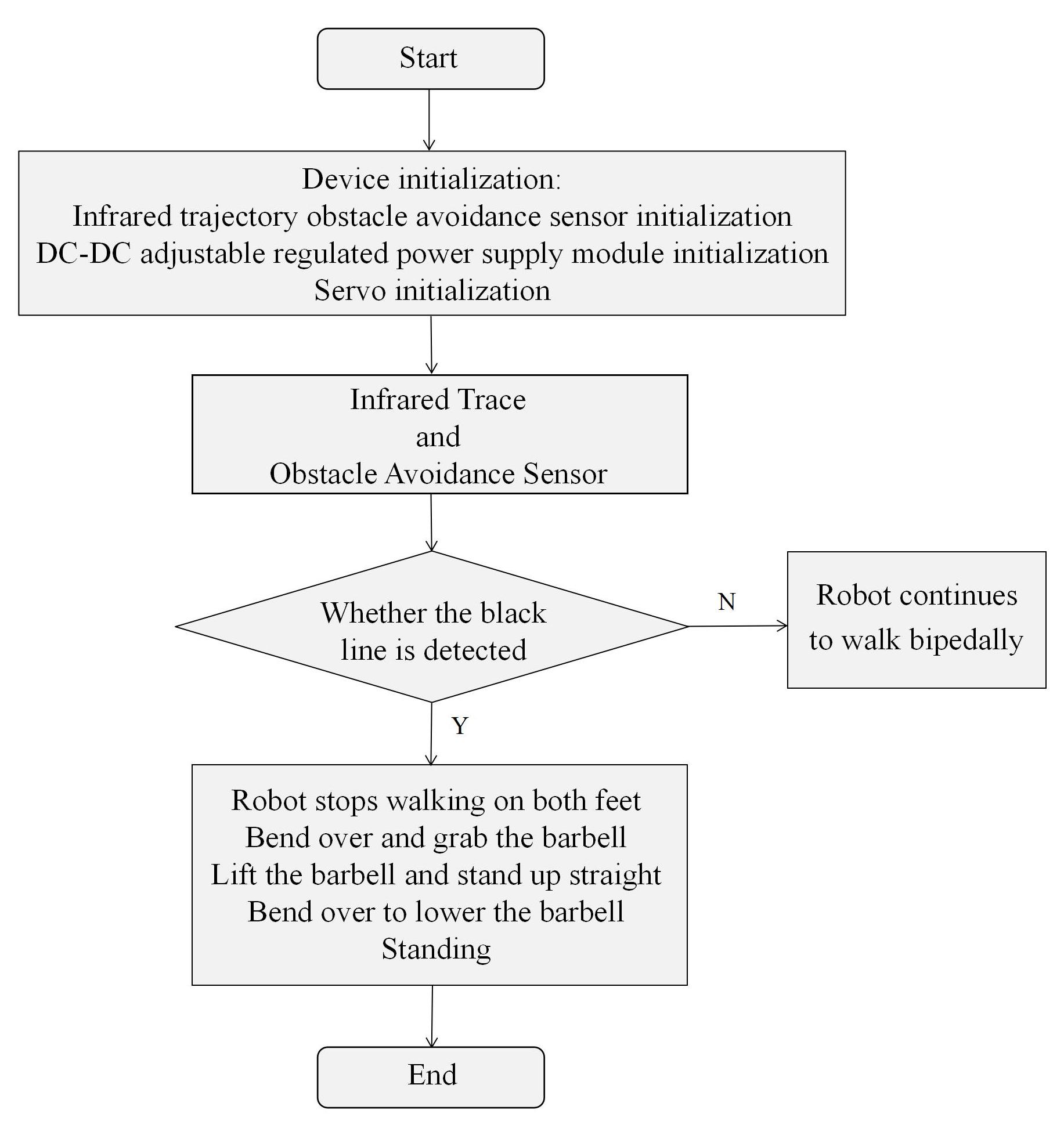

The "Weight Lifting Robot" as depicted in Figure 3, focuses on the design and manufacturing of the mechanical structure, including components such as the mechanical arm, grasping mechanism, and support structure. The design process involves careful consideration of material selection, mechanical analysis, and structural optimization to ensure that the robot can withstand heavy loads and perform lifting operations with precision.

The weightlifting robot case study serves as a robust validation of the proposed talent cultivation framework's scalability, demonstrating its efficacy in addressing core mechanical engineering competencies (structural integrity, dynamic stability, and precision control) through a systematic four-tier curricular progression (from foundational engineering experiences to advanced interdisciplinary integration). This implementation exemplifies the framework's dual adaptability: vertical specialization through progressively sophisticated content integration (e.g., finite element analysis in upper-division courses) and horizontal expansion via cross-disciplinary synthesis (e.g., mechatronic systems combining control theory with advanced materials science). The modular instructional design, coupled with a multi-phase assessment protocol, establishes a replicable yet customizable pedagogical model for intelligent manufacturing education, effectively bridging the gap between theoretical knowledge and practical engineering applications while maintaining flexibility for discipline-specific customization.

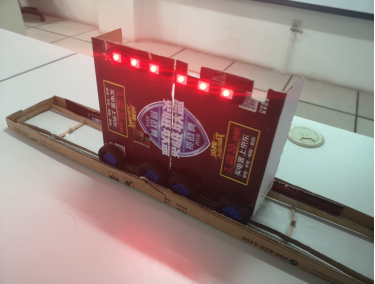

3) Automation and Control System Category:

The "Small Car Model Transformed into an Automatic Door" as shown in Figure 4, utilizes sensors to enable intelligent opening and closing of the door, as well as people counting. This project, closely related to real-life applications, demonstrates the students' initial exploration of integrating mechanical structures with sensor technologies.

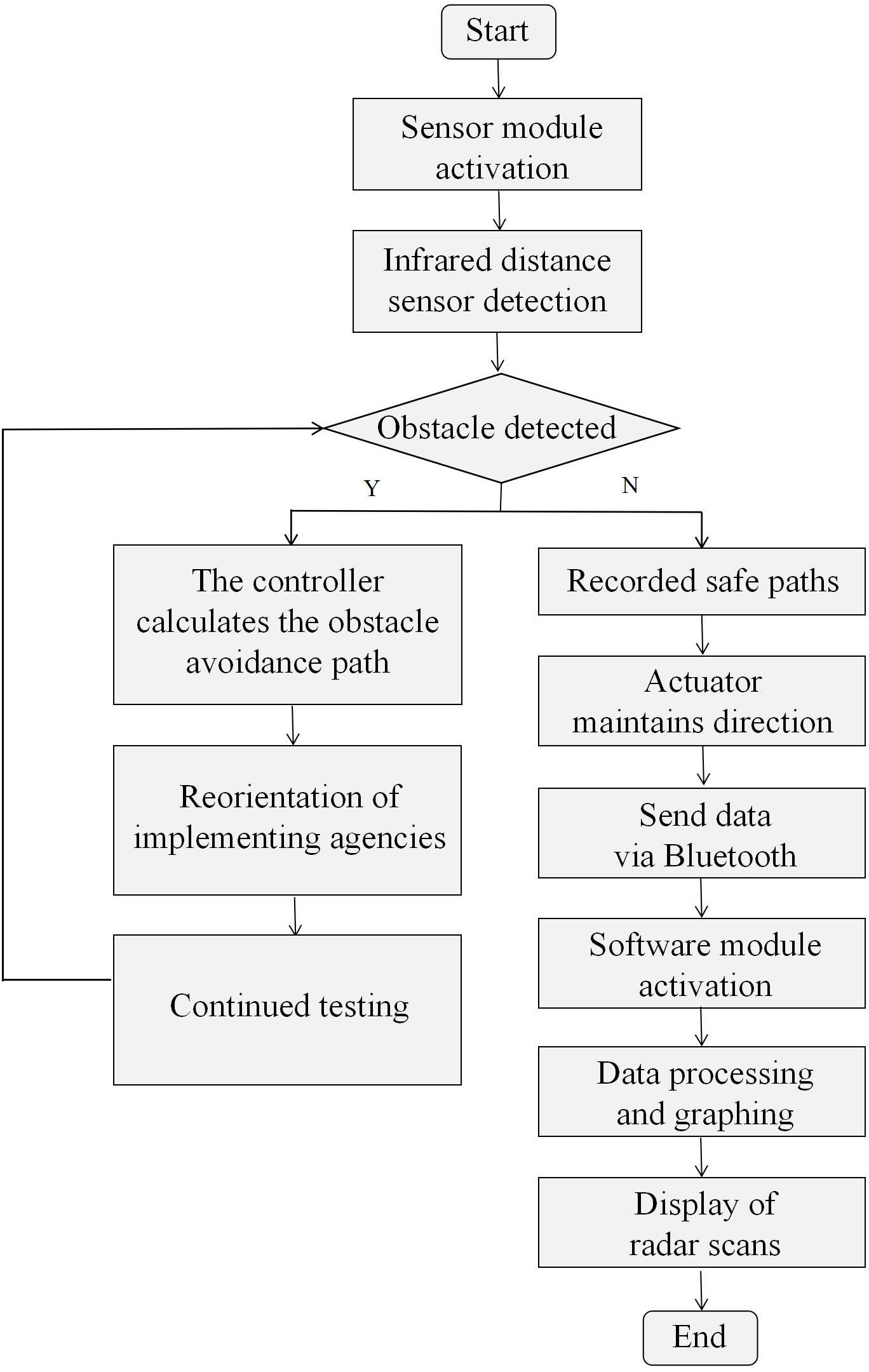

The "Radar Scanning and Mapping Cart" as depicted in Figure 5, is equipped with radar sensors that facilitate environmental scanning and mapping through data processing algorithms and embedded systems. The cart is capable of autonomously avoiding obstacles and generating a two-dimensional map of its surrounding environment.

This study systematically validates the scalability of the proposed smart manufacturing talent cultivation framework through two representative case studies: an automatic door trolley and a radar mapping trolley. The automatic door project serves as an ideal introductory platform for freshman engineering courses, effectively establishing fundamental interdisciplinary knowledge integrating mechanical, electronic, and control systems. In contrast, the radar mapping project provides an advanced comprehensive practice that demands mastery of sensor technologies, sophisticated data processing algorithms, and embedded system development. These complementary cases demonstrate the framework's "theory-practice" dual-loop mechanism, exhibiting a clear pedagogical progression from basic sensor applications to complex algorithmic implementations. The adaptable four-step evaluation scheme accommodates varying project complexities, ranging from fundamental functional verification to comprehensive multidimensional assessment encompassing algorithm design, system integration, and performance optimization. Through this tiered project structure and modular technical components, the framework successfully bridges foundational knowledge with innovative practice, thereby confirming both its universality and scalability in smart manufacturing education.

The objectives of the Freshman Engineering Experience course are to foster students' interest in hands-on practical skills, to provide an understanding of the professional training goals, and to equip students with the theoretical knowledge and methods necessary for addressing social needs and practical applications. The students' projects are closely aligned with these goals, demonstrating their proficiency in mechanical design, sensor technology, and the application of electroniccomponents. For instance, the weightlifting robot utilizes sensor technology for intelligent control, with the structure of the work shown in Figure 6.

Similarly, the radar scanning and mapping trolley autonomously avoids obstacles and generates a map of the surrounding environment, as illustrated in Figure 7. These projects reflect the students' understanding of automation and its application in enhancing convenience in daily life.

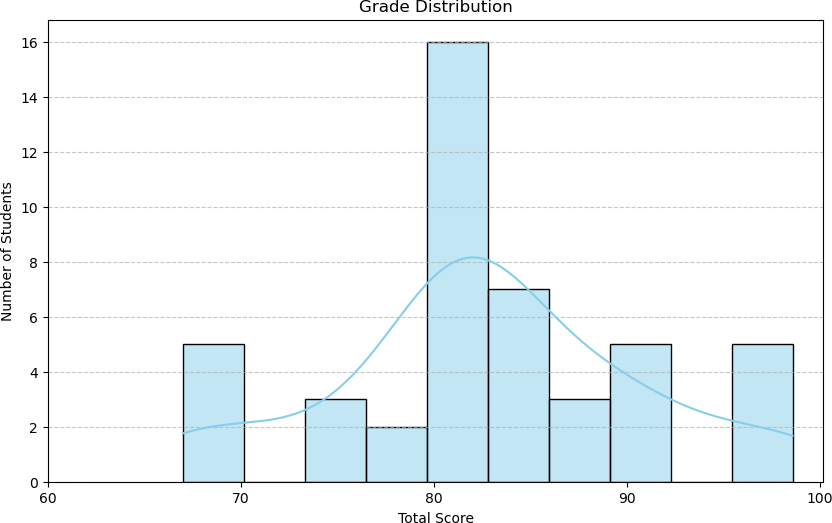

Statistical analysis of student grades in the "Freshman Engineering Experience" course for the 2022-2023 academic year revealed that the grades followed a normal distribution, with a concentration in the 70-90 point range. Additionally, the experimental results had a significant impact on the overall evaluation, with students demonstrating superior experimental abilities generally achieving higher overall scores. The statistical distribution of student results in the "Freshman Engineering Experience" course is presented in Figure 8. The peak of the kernel density curve is located in the 80-90 point range, which corresponds to the highest bar in the histogram, emphasizing the concentration of the majority of students' scores in this interval.

The "Freshman Engineering Experience" course, being introductory in nature, serves as both an overview of the professional curriculum for the next three years and a foundational cornerstone for students' learning of specialized content. Consequently, the effective introduction of professional knowledge and the construction of a cohesive knowledge framework for professional learning are of paramount importance. In this context, we have developed an educational framework based on new engineering content, selecting appropriate content and teaching methods to seamlessly integrate engineering and cultural education for automation majors, thereby facilitating students' acceptance and understanding. In the "Freshman Engineering Experience" course, the integration of scientific knowledge and culture enriches both the teaching reform methodologies and the educational theory behind the cultural education of "New Engineering," offering significant practical guidance for future instruction [23].

Following the implementation of this teaching reform, students within this specialty have generally gained a clearer understanding of the overall structure of professional knowledge and the interconnections between courses, which has effectively enhanced their motivation to learn and positively impacted their academic outcomes. Over the past five years, the course has led to 38 national discipline competition awards, including recognitions in the National College Students' Industrial Automation Challenge, as well as 114 first and second-place awards in provincial and ministerial competitions, totaling over 150 accolades. Furthermore, 13 innovation papers at the national level and 41 innovation papers at the provincial and ministerial levels have been completed by students. The pass rates for the fourth and sixth levels of the course exceed 90% and 40%, respectively, and seven students have received national scholarships. These outcomes reflect a significant improvement in the quality of student training and achievement.

Copyright © 2025 by the Author(s). Published by Institute of Emerging and Computer Engineers. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

Copyright © 2025 by the Author(s). Published by Institute of Emerging and Computer Engineers. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. IECE Transactions on Education and Learning Technologies

ISSN: request pending (Online)

Email: [email protected]

Portico

All published articles are preserved here permanently:

https://www.portico.org/publishers/iece/